1100 - Torque Monster Small Block Build

Building an 1100 A-Series engine to be a torque machine that can outperform some stock 1275 engines, with an exceptional power curve!

As you probably already know, I have built some seriously big power engines on my channel over the years. Most recently, I turbocharged my 1275 and produced over 200whp. And while these large power engines are a blast to drive, and exceptionally fun to build, this isn’t actually the ethos of the original Classic Mini.

If you haven’t seen the video - check it out here

Big fun, With Small Power

Minis were always about producing just the right amount of power to make their small lightweight stature an absolute blast to drive. This was true across the entire engine lineup, from the OG 850cc engine, all the way up to the hot 1275cc that was in later cars. Combine this with the absolute ease of working on these engines and people’s die-hard focus on squeaking out every little bit of power via new cams, new carbs, pistons, and more.

Building a Small Displacement Torque Machine

So now we get to look at our newest build: a tired 1100cc engine from a Charlotte local’s New Zealand import mini. What we originally thought was an 850 turned out to be an early 1100 with the original 12G202 head. This is excellent news because it puts us in a much different situation for a rebuild.

The 1100 Myth and Reality

Many people on the W O R L D W I D E W E B will tell you that 1100cc engines are “weak” or not that much different than a standard 998cc engine. I think this is largely due to some commentary from David Vizard that was taken out of context and blown out of proportion. Saying these engines are incredibly prone to cranks cracking or failing when revved high. While this is not incorrect, the impact is very over-stated in my opinion.

Here are the facts:

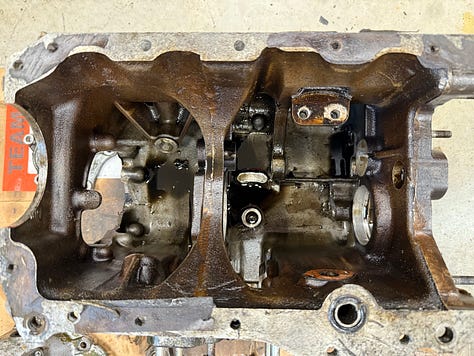

The 1100cc uses the same block as the 998cc engines did. This block is incredibly tough.

These engines use a special 12G82 crankshaft which has a longer stroke to increase displacement without needing larger cylinders

This results in considerably more torque than a standard 998, but it does reduce the safe redline to about 6500 rpm.

Most people do not drive their cars past 6500rpm in the real world on the road.

What the 1100 provides is an exceptional platform to produce considerably more useable power and torque in the normal power band (1k-5k rpm) and when built properly, can outperform many stock 1275 engines due to the more desirable power curve.

Engine Starting Point:

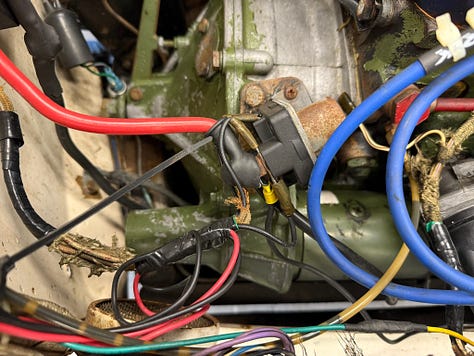

After taking it out of the car, getting it on the engine stand, and making an assessment, this is what we have…

Standard 1100cc (998cc block with special long-stroke crank)

12G202 Cylinder Head with ported intakes and exhausts (pictures below)

Very tired problematic 3-Synchro Gearbox with Magic Wand

Soaked clutch and Flywheel

3-Synchro Gearbox Situation

As mentioned above the Gearbox was absolutely in need of a complete rebuild. Unable to shift into second gear without terrible grinding, the shifter was bouncing all over the place, and in general it just needed some love.

After discussing with the owner, he decided he would like to preserve the original 3-synchro box and magic wand shifter. This, of course, kept the car original and like it was when it rolled off the assembly line.

Many people would insist on going with a later-style 4-synchro box, but there is something incredibly special about these early cars with the magic wand. They just have a different experience while driving, when you care for the parts themselves.

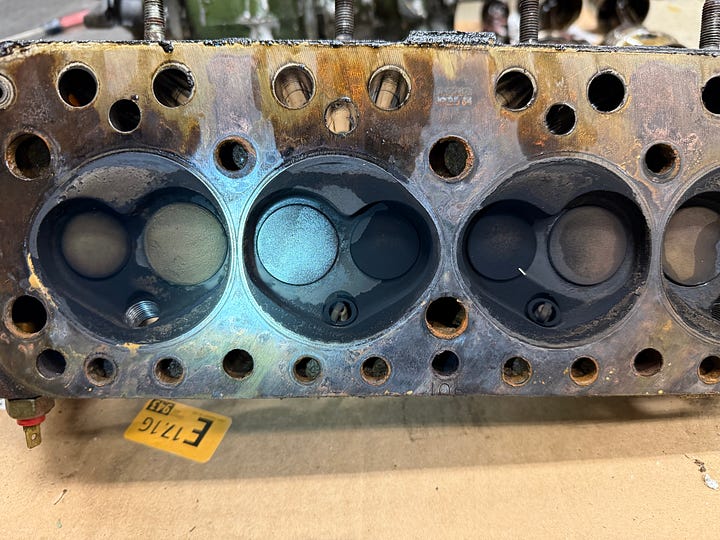

12G295 Cylinder Head

This is probably the most exciting find about this build, this original “chunky” 1100 cylinder head. These heads have a ton of extra meat to help with porting and polishing. In addition, they will tolerate more material being taken out of the chambers to decompress the chambers. I will get deeper into this in a dedicated post.

The intake and exhaust runners do also look a bit smoother and wider than stock would as well. We dont know for sure, but this does appear to have some porting/polishing done to help make this head breath better. This is going to be incredibly helpful with the larger valves we are installing as part of this build.

Final thoughts - Stay Tuned!!

So we are in for an extremely exciting project as we get this engine machined, and prepped for some serious torque and power! The goal of this engine is to build up our customer’s car to be exceptionally fun on the road, in the mountains, and as a daily driver. Offering the ability to easily keep up with traffic on the road, and highway. While also producing a car that can be driven in a spirited way for many years to come!

I will be posting more videos on my YouTube channel of course, and shortly after each video, I will post deep dives into some of the concepts here on Substack.